In pharmaceutical production, even the slightest change in humidity can ruin a product. Excessive humidity might cause breakdown of tablets, clumping of powder, or bacterial growth; unstable humidity may also affect the drug's strength. Pharmaceutical dehumidifiers play a vital role in maintaining stable humidity levels and thereby ensuring the drug's safety, efficacy, and shelf life. Learn more about their importance, functioning, and role in ensuring stringent industry standards.

Why Humidity Control is Essential in Pharma Manufacturing

Pharmaceuticals are highly susceptible to moisture. For example, vitamins or antibiotics can become spoiled in humidities greater than 60% and lose their effectiveness or even be fatal. Dryness, however, can cause raw materials to dry out, making processing problematic. For example, when powders are being mixed, proper humidity is critical in maintaining their texture.

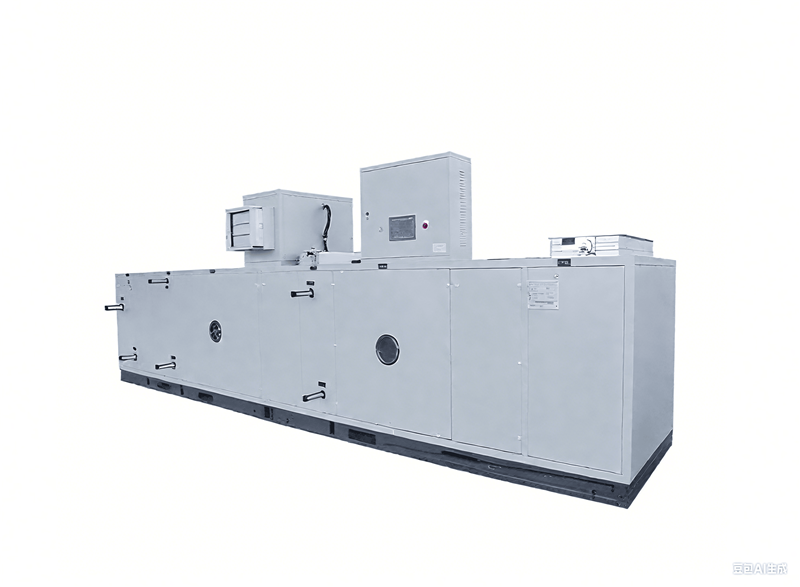

Pharmaceutical dehumidifiers resolve this issue by maintaining the humidity level at 30% to 50%. Stability offered not only protects raw materials and prevents fungal growth, but also prevents rust or equipment failure. It also facilitates regulation compliance, such as the EU's Good Manufacturing Practices, requiring strict control of the environment to ensure pharmaceutical quality.

How Pharmaceutical Dehumidifiers Work

These are advanced versions of domestic models and use desiccant wheels or refrigeration to pull water out of the air. Desiccant systems also work well in cold environments: they use mediums like silica gel that inhale moisture, dry it, and recycle it.

For large spaces like warehouses for raw material storage, industrial dehumidifiers can handle massive volumes of air to ensure that every corner remains dry. Some can even be made part of intelligent systems for real-time humidity level monitoring, with alerts sent whenever levels deviate from the standard. This consistency is necessary; even a small area with excessive humidity can ruin the quality of an entire medicine batch.

Notably, pharmaceutical dehumidifiers can adapt to adverse weather conditions. Under highly wet atmospheric environments, for instance, in tropical regions, they work more aggressively to remove surplus wetness from penetrating the production sectors. In arid regions, they sustain humidity and do not over-dry, which is critical in the preservation of delicate raw materials.

Special Spaces: Pharmaceutical Dry Rooms

Many pharmaceuticals are produced or stored in dry rooms, where humidity levels are extremely low. This requires a dedicated pharmaceutical drying room solution: a dehumidifier combined with a sealed structure and monitoring system to maintain stable humidity 24 hours a day.

For example, in the production of injectable drugs, powders must be dry to facilitate easy blending. A drying room equipped with a high-capacity dehumidifier offers the guarantee that water will not destroy the quality of the powder. Professional pharmaceutical dehumidification drying room suppliers pay attention to the design of these rooms to the demanding standards of the industry, typically designing them for specific drugs or phases of production. They may also incorporate additional features, such as air filtration to remove contaminants, to create a fully controlled environment.

How to Choose the Right Dehumidifier

Not all dehumidifiers are suited for the pharmaceutical industry. Pharmaceutical businesses require models meeting regulatory requirements. When choosing a dehumidifier, remember the following:

Accuracy: Humidity control needs to be ±2% in order to avoid fluctuations.

Reliability: Enables uninterrupted operation in huge plants without compromising performance.

Scalability: One can utilize many devices connected together via a central system in a large factory.

Hangzhou Dry Air, a China wholesale pharmaceutical dehumidifier manufacturer, has an enormous range of options, starting from small laboratory equipment to large industrial apparatus, to suit facilities of all sizes. We also offer after-sales services, such as calibration services and maintenance services, to support prolonged stable operation of the system. We also have tailor-made solutions, modifying dehumidifiers to the specific layout and needs of pharmaceutical plants.

Benefits Beyond Safety

Good humidity control not only ensures drug safety but also:

Reduced Waste: A stable environment reduces batch rejections, saving raw materials and time.

Cost Savings: Trash and equipment maintenance reduced lower long-term costs.

Increased Efficiency: Dry weather supports unbroken production processes without interruptions for humidity adjustments, thereby ensuring yields.

Extended Shelf Life of Product: By avoiding moisture-associated degradation, medicines last longer and fewer recalls are required.

Conclusion

Pharmaceutical dehumidifiers are essential to drug manufacturing producing safe and effective drugs. Pharmaceutical dehumidifiers control humidity to protect raw materials, comply with regulations, and avoid production downtime. In small laboratories to large plants, the proper dehumidifier is essential to drug quality.

Call us for more information regarding pharmaceutical dehumidifiers.

Post time: Aug-26-2025